The Design & Engineering Behind the New Model Y [Video]

Tesla’s Model Y has held the title of the world’s best-selling vehicle—across all categories—for the past three years. And it takes an absolute masterstroke of engineering and design to make an even better, more popular vehicle.

In a newly released video (posted below), Tesla highlights some of the key upgrades and refinements made to the Model Y. While a previous deep dive explored the engineering details [insert link here], this latest video offers a broader look at the improvements. Let’s take a closer look.

Unique Design of the Model Y

The refreshed Model Y is all about individuality. While every Tesla model stands out in its own way, some are more similar than others. For example, the Model S and Model X share a similar front fascia design but still feel distinct. The previous Model 3 and Model Y, however, were often difficult to differentiate, even for seasoned Tesla owners.

That’s no longer the case. With the refreshed Model 3 and Model Y, the differences are clear enough to make each vehicle instantly recognizable. You’ll easily spot them on the road and distinguish them from their predecessors.

Design

The lightbar is the first thing you’ll notice about the design overhaul. Tesla aimed to give the vehicle a wider, more grounded appearance while also creating more space on the front fascia. This newfound space not only improves the vehicle’s look but also leads to some efficiency gains—more on that later.

The rear lightbar is equally striking. It’s a reflective, full-body design, marking a first in the automotive industry. The light is reflected onto a custom applique, which directs it downward, creating a puddle of red light behind the car. As Franz, Tesla’s Head of Design puts it, it gives the impression of an afterburner.

Ride Comfort

Tesla has been focused on improving ride comfort, and the refreshed Model Y is a testament to that effort. While the original Model Y had more of a sports car-like handling, which was less ideal for family use, the new suspension design focuses on comfort by reducing impact harshness, all while maintaining Tesla’s signature steering feel and precise handling.

This is paired with in-house designed tires, developed alongside the tire manufacturer, resulting in the most efficient EV tires Tesla has ever used. With lower rolling resistance, improved handling, and reduced road noise, these tires contribute to a smoother, quieter ride.

The addition of acoustic glass across every glass surface in the vehicle, combined with upgraded sealing materials throughout the cabin and body, has led to a 20% reduction in overall vehicle noise. This is a substantial improvement for an already quiet EV.

The new silver-infused acoustic glass also reflects heat much more effectively than the older glass, reducing the strain on the vehicle’s climate system. This allows the fan to run at a lower speed, further reducing cabin noise and improving energy efficiency. Tesla has truly pulled out all the stops to make the refreshed Model Y one of the most comfortable and refined passenger vehicles on the road.

Efficiency and EPA Range

When it comes to efficiency, Tesla has meticulously reevaluated every component and design choice of the original Model Y, all while maintaining the same size and form factor that has made it a favorite for millions worldwide. The result? A 10% improvement in efficiency over the previous Model Y, which translates to more range.

The EPA recently announced the official range for the vehicle of 327 miles, beating Tesla’s estimate of 320 miles. This is an increase of 16 miles over the outgoing AWD Model Y, which had an EPA estimated range of 311 miles.

The front ducts have been widened thanks to changes in the front fascia, allowing for improved airflow over the tires and front brakes. Meanwhile, the new thermoplastic spoiler has been redesigned at the rear to be more aerodynamically efficient, contributing to the overall 10% efficiency boost. These updates improve performance and range.

Utility

The Model Y has become the ubiquitous Sports Utility Vehicle, capable of handling just about anything. In addition to improving its performance and efficiency, Tesla has also improved its practicality. The trunk opening has been enlarged, making it easier to load and unload items.

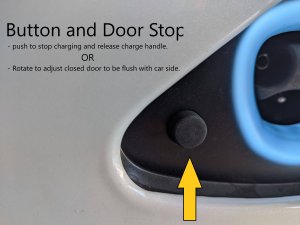

One standout feature is the power-folding rear seats. With just the push of a button, you can effortlessly fold them down or raise them back up. Additionally, the front seats automatically slide forward to create more space when you need to bring the rear seats down.

Tesla also gave the frunk a thoughtful upgrade. It now includes a new drain plug, and the bottom liner is fully waterproof—an improvement over the previous water-resistant version. This means you can fill the frunk with ice or use Tesla’s upcoming frunk cooler without worry. There’s even talk of more accessories on the horizon, and we can’t wait to see what Tesla has in store for this versatile space.

Safety

Safety has always been a top priority in Tesla’s vehicle design, and the Model Y has consistently earned 5-star crash safety ratings worldwide. It’s expected that the refreshed Model Y will continue this trend, maintaining Tesla's reputation for top-tier safety.

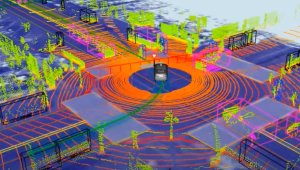

Additionally, the new front bumper camera offers valuable assistance for parking in tight spaces or when navigating off-road. While there’s no official word yet on whether these bumper cameras will be integrated into Full Self-Driving (FSD) or Smart Summon for the refreshed Model Y or Cybertruck, it’s definitely something to watch for in future updates.

Interior

Inside the refreshed Model Y, Tesla has fine-tuned every detail to create a more premium feel. This includes the addition of ambient lighting, similar to the refreshed Model 3 and Cybertruck, as well as new materials throughout the cabin to elevate the overall aesthetic.

The redesigned heated and ventilated seats take comfort and support to the next level, which is a significant improvement for those who use the Model Y as their daily commuter. A comfortable seat can make all the difference on long drives.

In the rear, the updated infotainment system can now pair with two Bluetooth headsets specifically for the back screen. This means passengers in the rear can enjoy audio independently of the front, so if your kids want to watch cartoons, you can continue enjoying music or the news without any interruptions.

Tesla also developed new acoustically transparent materials, which are used to conceal some of the 16 speakers and the newly positioned microphones. Placing the microphones closer to the driver and front passenger’s heads improves clarity for voice recognition and phone calls.

Be sure to check out the full video below to see the meticulous design work and thoughtful improvements that went into the refreshed Model Y—it’s definitely worth a watch.

Design & engineering walkthrough of New Model Y pic.twitter.com/2jvMQOXGkM

— Tesla (@Tesla) February 8, 2025

![Tesla’s Hollywood Diner: In-Car Controls & Theater Screens Turned On [VIDEO]](https://www.notateslaapp.com/img/containers/article_images/2025/tesla-diner.webp/3aaa2ea0edf2eaa0fabe1217530f3476/tesla-diner.jpg)

_300w.png)